In the ever-evolving landscape of sustainable agriculture and waste management, the utilization of cow dung as a valuable resource has gained significant traction. This nutrient-rich byproduct, once considered a mere waste stream, has emerged as a powerful organic fertilizer and soil amendment, offering numerous benefits for crop production and environmental stewardship.However, handling and applying raw cow dung can be a challenging and labor-intensive process, often accompanied by unpleasant odors and potential health risks.

Enter the cow dung pellet making machine – an innovative technology that transforms this organic waste into a convenient, easy-to-handle, and highly effective fertilizer product. These specialized machines are designed to efficiently process cow dung and convert it into dense, uniform pellets, unlocking the full potential of this valuable resource. In this article, we’ll explore the cutting-edge features of cow dung pellet making machines, highlighting their capabilities and the benefits they offer to farmers, gardeners, and environmentally conscious individuals.

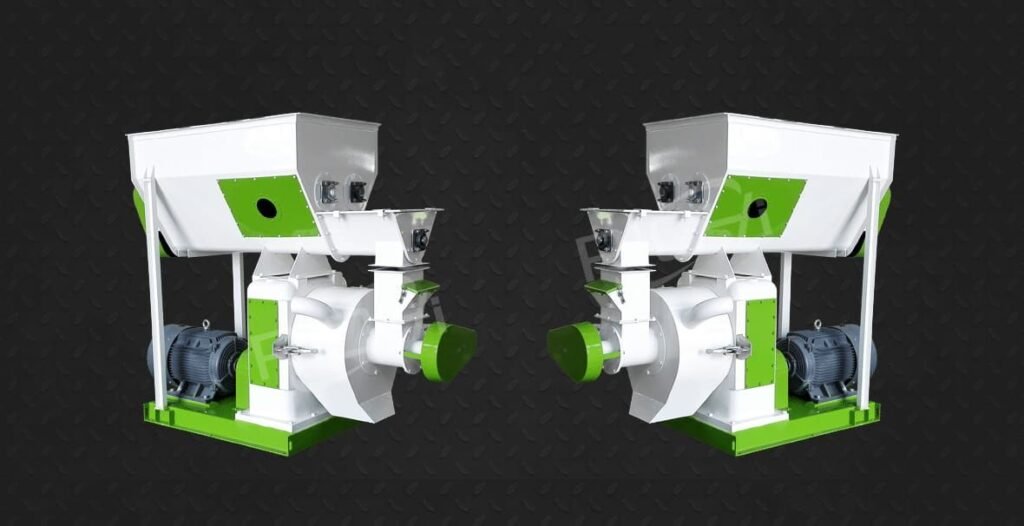

Robust and Durable Construction

Cow dung pellet making machines are engineered to withstand the rigors of continuous operation and the harsh environments often associated with agricultural and waste management settings. These machines are typically constructed using high-quality materials, such as stainless steel or heavy-duty cast iron, ensuring durability and resistance to corrosion and wear.Additionally, many machines feature reinforced frames and sturdy support structures, providing stability and minimizing vibrations during operation. This robust construction not only enhances the machine’s longevity but also contributes to consistent pellet quality and reduced maintenance requirements.

Efficient and Versatile Pelletizing Mechanisms

At the heart of these machines lies the pelletizing mechanism, which is responsible for transforming raw cow dung into dense, cylindrical pellets. Cow dung pellet making machines employ various pelletizing technologies, each with its own unique advantages and capabilities.One common mechanism is the ring die pelletizing system, which utilizes a rotating ring die and rollers to compress and extrude the cow dung through small holes, forming uniform pellets.

This system is known for its high production rates and ability to handle a wide range of raw materials.Alternatively, some machines employ flat die pelletizing mechanisms, which use a flat die plate with multiple holes and a rotating roller to extrude the pellets. This design offers greater flexibility in adjusting pellet dimensions and can produce pellets with intricate shapes or textures.Regardless of the specific pelletizing mechanism, these machines are designed to operate efficiently, minimizing energy consumption and maximizing output while maintaining consistent pellet quality.

Related post: https://www.richipelletmachine.com/horse-manure-pellet-maker/

Advanced Material Handling and Pre-Processing Features

Cow dung pellet making machines often incorporate advanced material handling and pre-processing features to streamline the production process and ensure optimal pellet quality. These features may include:

- Automated Feeding Systems: Many machines are equipped with automated feeding systems that regulate the flow of raw cow dung into the pelletizing mechanism, ensuring a consistent and controlled input rate.

- Drying and Conditioning Units: To achieve the optimal moisture content for pelletizing, some machines integrate drying or conditioning units that remove excess moisture from the raw cow dung, improving pellet quality and reducing the risk of spoilage.

- Grinding and Mixing Components: Certain models feature integrated grinding and mixing components that break down large clumps of cow dung and ensure a homogeneous mixture before pelletizing, enhancing pellet consistency and nutrient distribution.

- Screening and Separation Systems: After pelletizing, some machines incorporate screening and separation systems to remove any oversized or undersized pellets, ensuring a uniform final product and minimizing waste.

These advanced features not only improve the efficiency and quality of the pelletizing process but also contribute to the overall automation and ease of operation, reducing the need for manual intervention and labor-intensive tasks.

User-Friendly Controls and Automation

Modern cow dung pellet making machines are designed with user-friendly controls and automation features, making them accessible and easy to operate for a wide range of users. These machines often feature intuitive control panels or touchscreen interfaces that allow operators to monitor and adjust various parameters, such as pellet size, production rate, and temperature settings.

Additionally, many machines incorporate advanced automation systems that can automatically adjust and optimize the pelletizing process based on real-time data and feedback, ensuring consistent pellet quality and maximizing production efficiency.These user-friendly controls and automation features not only simplify the operation of the machines but also contribute to increased productivity, reduced downtime, and improved safety for operators.

Energy Efficiency and Sustainability

In line with the principles of sustainable agriculture and waste management, cow dung pellet making machines are designed with energy efficiency and environmental responsibility in mind. Many manufacturers incorporate energy-saving technologies, such as variable frequency drives or regenerative braking systems, to minimize energy consumption and reduce operational costs.

Furthermore, some machines are designed to integrate with renewable energy sources, such as solar panels or biogas generators, further reducing their environmental impact and promoting sustainable practices.By prioritizing energy efficiency and sustainability, these machines not only contribute to the reduction of greenhouse gas emissions and environmental pollution but also offer long-term cost savings and align with the growing demand for eco-friendly products and practices.

Versatility and Scalability

Cow dung pellet making machines are available in a wide range of sizes and configurations, catering to the diverse needs of various users, from small-scale farmers and gardeners to large-scale commercial operations. This versatility allows users to select a machine that aligns with their specific production requirements, available space, and budget constraints.Additionally, many machines are designed with scalability in mind, offering the ability to expand or upgrade components as production demands increase.

This scalability ensures that users can adapt to changing market conditions and growth opportunities without the need for costly equipment replacements.By offering versatility and scalability, cow dung pellet making machines provide a flexible and future-proof solution for those seeking to capitalize on the growing demand for organic fertilizers and sustainable agricultural practices.

As the world continues to embrace sustainable practices and circular economy principles, the innovative features of cow dung pellet making machines position them as valuable tools for transforming organic waste into valuable resources.

By leveraging these cutting-edge technologies, farmers, gardeners, and environmentally conscious individuals can contribute to sustainable agriculture, promote soil health, and reduce their reliance on synthetic fertilizers, all while minimizing waste and promoting environmental stewardship.